Mohala oa ho Sibolla Margarine oa Puff Pastry

Mohala oa ho Sibolla Margarine oa Puff Pastry

Video ea Tlhahiso:https://www.youtube.com/watch?v=3cSJknMaYd8

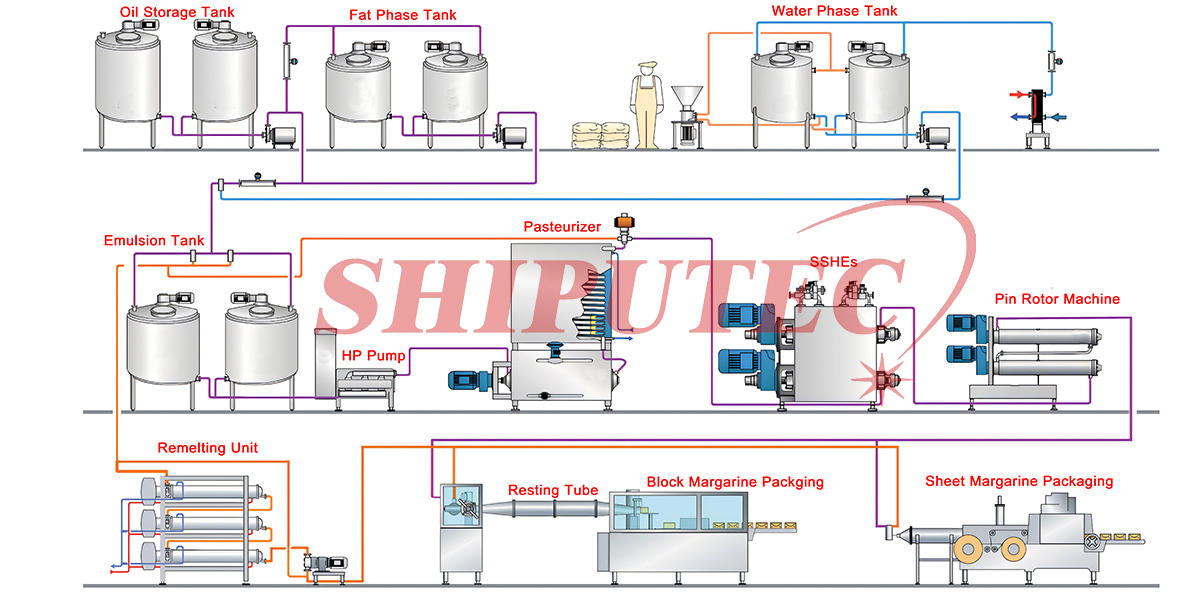

Margarine ke sebaka sa botoro se entsoeng ka oli ea meroho, mafura a liphoofolo kapa mehloli e meng ea mafura. Mokhoa oa tlhahiso ea eona le lisebelisoa tsa ts'ebetso li se li holile haholo kamora lilemo tsa nts'etsopele. Tse latelang ke phallo e qaqileng ea ts'ebetso le kenyelletso ea lisebelisoa tsa bohlokoa:

I. Ts'ebetso ea Tlhahiso ea Margarine

1. Tokisetso ea Lisebelisoa tse Tala

• Lisebelisoa tse tala tsa mantlha:

o Oli (hoo e ka bang 80%): tse kang oli ea palema, oli ea soya, oli ea peo ea rapeseed, oli ea kokonate, jj., tse hlokang ho hloekisoa (ho tlosa mamina, ho tlosa asiti, ho tlosa 'mala, ho tlosa monko o mobe).

o Mokhahlelo oa metsi (hoo e ka bang 15-20%): lebese le sa tsoakoang, metsi, letsoai, li-emulsifier (tse kang lecithin, mono-glyceride), lintho tse bolokang mongobo (tse kang potassium sorbate), livithamine (tse kang vithamine A, D), linoko, jj.

o Lintho tse ekelitsoeng: 'mala (β-carotene), taolo ea asiti (lactic acid), jj.

2. Ho Kopanya le ho Emulsification

• Mokhahlelo oa oli le mokhahlelo oa metsi:

o Mokhahlelo oa oli (oli + lintho tse eketsang oli) o futhumatsoa ho fihlela ho 50-60℃ ebe oa qhibiliha.

o Mokhahlelo wa metsi (metsi + di-additives tse qhibilihang ka metsing) o futhumatswa mme o hlwekiswa (ho pasteurization, 72℃/metsotsoana e 15).

Mekhahlelo ena e 'meli e kopanngoa ka tekanyo, 'me li-emulsifier (tse kang mono-glyceride, soy lecithin) lia eketsoa, 'me emulsion e tšoanang (mofuta oa metsi ka har'a oli kapa oli ka har'a metsi) e thehoa ka ho hlohlelletsa ka lebelo le phahameng (2000-3000 rpm).

3. Ho phodisa le ho etsa kristale ka potlako (Mohato oa Bohlokoa)

• Ho pholisa ka potlako: Emulsion e pholisoa ka potlako ho fihlela ho 10-20℃ ka sesebelisoa sa ho fapanyetsana mocheso oa bokaholimo (SSHE), e leng se bakang ho kristale ho sa fellang ha oli ho etsa sebopeho sa kristale sa β' (senotlolo sa sebopeho se setle).

• Ho Bopa: Mafura a tiileng hanyane a sehoa ka mochini ka har'a kneader (Pin Worker) ka lebelo la 2000-3000 rpm ho roba likristale tse kholo le ho etsa sebopeho se setle le se ts'oanang sa marang-rang a mafura, ho qoba maikutlo a ho thothomela.

4. Ho holisa le ho paka

• Ho hola: E tlohelwa hore e eme mochesong wa 20-25℃ ka dihora tse 24-48 ho tsitsisa sebopeho sa kristale.

• Sephutheloana: E tlatswa e le diboloko, dikopi, kapa mofuta wa spray, mme e bolokwa ka sehatsetsing (margarine e bonolo e ka bolokwa mochesong wa kamore ka ho toba).

II. Lisebelisoa tsa Ts'ebetso ea Motheo

1. Lisebelisoa tsa pele ho kalafo

• Lisebelisoa tsa ho hloekisa oli: ho tlosa gumming centrifuge, tora ea ho tlosa asiti, tanka ea ho tlosa 'mala, tora ea ho tlosa monko o mobe.

• Lisebelisoa tsa ho sebetsana le mohato oa metsi: mochini oa ho etsa li-pasteurization, homogenizer ea khatello e phahameng (e sebelisetsoang ho kopanya lebese kapa mohato oa metsi).

2. Lisebelisoa tsa Emulsification

• Tanka ea emulsion: tanka ea tšepe e sa ruseng e nang le mesebetsi ea ho tsikitlanya le ho futhumatsa (joalo ka sehokelo sa ho tsikitlanya kapa mofuta oa turbine).

• Homogenizer e nang le khatello e phahameng: ntlafatsa marotholi a emulsion haholoanyane (khatello ea 10-20 MPa).

3. Lisebelisoa tsa ho Pholisa ka Potlako

• Sehokelo sa Mocheso o Hohlang (SSHE):

o E pholisa ka potlako ho fihlela e hoama hanyane, ka sekere se potolohang ho thibela ho hola.

o Mefuta e tloaelehileng: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (USA), Shiputec (Chaena)

• Mosebetsi oa Pin:

o Seha mafura ka disete tse ngata tsa dipini ho laola boholo ba kristale.

4. Lisebelisoa tsa ho Paka

• Mochini o tlatsang ka boiketsetso: bakeng sa liboloko (25g-500g) kapa sephutheloana sa libarele (1kg-20kg).

• Mohala oa ho paka o sa hloekang: o loketse lihlahisoa tse tšoarellang nako e telele (joalo ka margarine e metsi e phekotsoeng ka UHT).

III. Mefuta e fapaneng ea Ts'ebetso

1. Margarine e Bonolo: Karolo e kholo ea oli e metsi ka har'a oli (joalo ka oli ea sonobolomo), ha ho hlokahale hore ho pholisoe ka potlako, e kopantsoe ka ho toba le ho pakoa.

2. Margarine e nang le mafura a tlase: Bongata ba mafura 40-60%, bo hloka ho eketsoa ha metsoako e teteanang (joalo ka gelatin, starch e fetotsoeng).

3. Margarine e Thehiloeng Limeleng: Foromo ea oli ea limela tsohle, ha e na li-trans fatty acids (fetola ntlha ea ho qhibiliha ka phapanyetsano ea ester kapa theknoloji ea karohano).

IV. Lintlha tsa Bohlokoa tsa Taolo ea Boleng •

Sebopeho sa kristale: Sebopeho sa kristale sa β' (se fetang sebopeho sa kristale sa β) se hloka taolo ea sekhahla sa ho tima le matla a ho kopanya.

• Polokeho ea likokoana-hloko: Karolo ea metsi e hloka ho hloekisoa ka thata, 'me pH e lokela ho fetoloa ka tlase ho 4.5 ho thibela libaktheria.

• Ho tsitsa ha oxidation: Kenya li-antioxidants (tse kang TBHQ, vithamine E) ho qoba tšilafalo ea li-ion tsa tšepe.

Ka ho kopanya lits'ebetso le lisebelisoa tse boletsoeng ka holimo, setlolo sa maiketsetso sa sejoale-joale se ka etsisa tatso ea botoro ha se ntse se fihlela litlhoko tsa bophelo bo botle tse kang k'holeseterole e tlase le mafura a tlase a khotše. Foromo le ts'ebetso e ikhethileng li hloka ho fetoloa ho latela sebaka sa sehlahisoa (joalo ka ho baka kapa ho sebelisoa holim'a lijo).

Ho Laela Sebaka