Mohala oa Tlhahiso ea Sauce ea Custard

Mohala oa Tlhahiso ea Sauce ea Custard

Mohala oa Tlhahiso ea Sauce ea Custard

Video ea Tlhahiso:https://www.youtube.com/watch?v=AkAcycJx0pI

Amohala oa tlhahiso ea soso ea custarde kenyelletsa letoto la lits'ebetso tse iketsang le tse iketsang hanyane ho etsa soso ea custard ka katleho, ka mokhoa o tsitsitseng le ka bohloeki. Ka tlase ke tlhaloso e qaqileng ea mekhahlelo e tloaelehileng moleng oa tlhahiso ea soso ea custard:

1. Ho sebetsana le ho lokisa metsoako

- Ho Amohela le ho Boloka Lebese

- Lebese le sa tsoakoang lea amoheloa, le hlahlojoa boleng ba lona, 'me le bolokoa ka har'a li-silo tse sehatsetsing.

- Mokhoa o mong: Phofo ea lebese e tsosolositsoeng + metsi (bakeng sa nako e telele ea ho e boloka).

- Ho sebetsana le Tsoekere le Setlolo

- Tsoekere, sirapo ea poone, kapa lintho tse ling tse monate lia beoa le ho qhibiliha.

- Ho Sibolloa ha Phofo ea Mahe le Mahe

- Mahe a metsi (a pasteurized) kapa phofo ea lehe a kopantsoe le metsi.

- Setache le Li-Stabilizer

- Setache sa poone, starch e fetotsoeng, kapa lintho tse thickeners (mohlala, carrageenan) li kopanngoa esale pele ho thibela ho kopana ha tsona.

- Linoko le Lintho tse Ekelitsoeng

- Vanilla, caramel, kapa tatso tse ling, hammoho le lintho tse bolokang mongobo (haeba ho hlokahala), lia lokisoa.

2. Ho Kopanya le ho Kopanya

- Ho kopanya ka sehlopha kapa ho tswela pele

- Lisebelisoa li kopanngoa kamotsoako o nang le sekere se phahamengkapatanka ea pele ho motsoakotlas'a mocheso o laoloang (ho qoba ho teteana pele ho nako).

- Homogenization e ka sebelisoa bakeng sa sebopeho se boreleli.

3. Ho pheha le ho etsa hore e be pasteurization

- Ho Pheha ka ho Tsoela Pele (Sehokelo sa Mocheso se Metsuoang)

- Motsoako o futhumatsoa ho75–85°C (167–185°F)ho kenya tshebetsong starch gelatinization le ho teteanya sauce.

- Ho etsa hore e be pasteurization (HTST kapa Batch)

- Nako e Khutšoane ea Mocheso o Phahameng (HTST) ho72°C (161°F) metsotsoana e 15-20kapa ho etsa pasteurization ka bongata ho netefatsa polokeho ea likokoana-hloko.

- Mokhahlelo oa ho Pholisa

- Ho pholisa ka potlako ho ea ho4–10°C (39–50°F)ho emisa ho pheha ho eketsehileng le ho boloka sebopeho.

4. Homogenization (Ka boikhethelo)

- Homogenizer ea Khatello e Phahameng

- E sebelisoa bakeng sa sebopeho se boreleli haholo (e thibela ho ba le lithollo).

5. Ho Tlatsa le ho Paka

- Mechini ea ho Tlatsa ka Boiketsetso

- Ho tlatsa mokotla(bakeng sa mabenkele) kapaho tlatsa ka bongata(bakeng sa tšebeletso ea lijo).

- Ho tlatsa ha aseptic(bakeng sa bophelo bo bolelele ba polokelo) kapaho tlatsa ka mocheso(bakeng sa polokelo e potolohileng).

- Mekhoa ea ho Paka:

- Libotlolo tsa polasetiki, mabokose, mekotlana, kapa makotikoti.

- Ho hlatsoa naetrojene ho ka sebelisoa ho eketsa nako ea ho boloka.

6. Ho Pholisa le ho Boloka

- Ho Fokotsa ho Chesang (haeba ho hlokahala)

- Bakeng sa custard e sehatsetsing, e pholise ka potlako ho fihlela4°C (39°F).

- Polokelo e batang

- E bolokiloe ho4°C (39°F)bakeng sa custard e foreshe kapa tikoloho bakeng sa dihlahiswa tse phekotsweng ka UHT.

7. Taolo le Teko ea Boleng

- Liteko tsa ho hlaka ha seretse(ho sebelisoa li-viscometer).

- Tlhokomelo ea pH(sepheo: ~6.0–6.5).

- Teko ea Microbiology(palo yohle ya dipoleiti, tomoso/hlobo).

- Tlhahlobo ea Kutlo(tatso, sebopeho, 'mala).

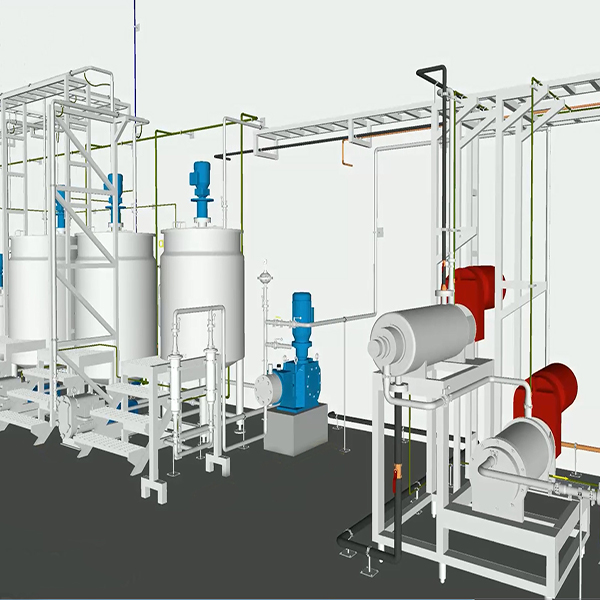

Lisebelisoa tsa Bohlokoa Moleng oa Tlhahiso ea Sauce ea Custard

- Litanka tsa Polokelo(bakeng sa lebese, metsoako e metsi).

- Mekhoa ea ho Bekha le ho Lekanya.

- Litanka tsa ho kopanya tse nang le moriri o molelele le tse kopantsoeng pele.

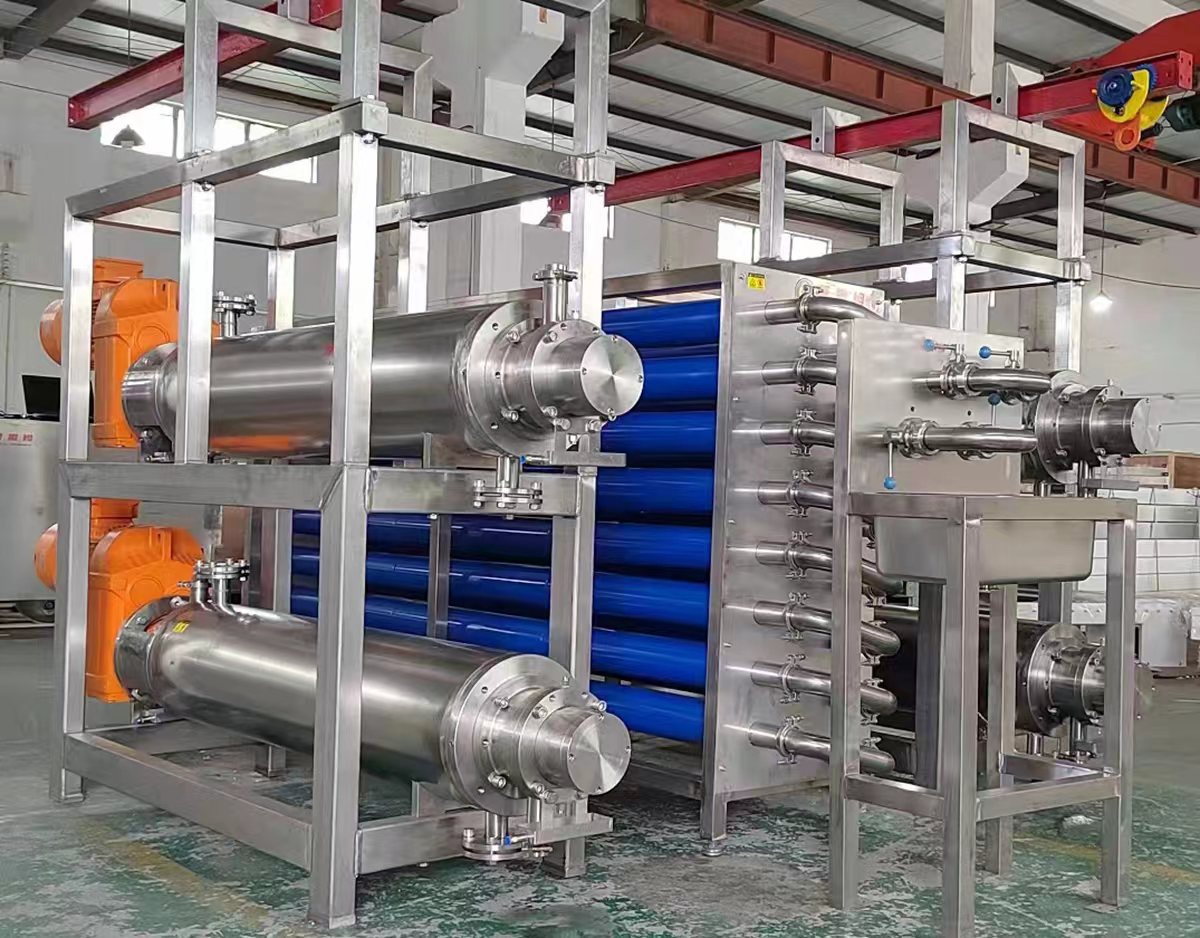

- Setlolo sa ho ntsha dipasteurizer (HTST kapa Batch).

- Mochini o Chesang oa ho Chesa o Hlakileng (bakeng sa ho pheha).

- Homogenizer (ha ho hlokahale).

- Mechini ea ho Tlatsa (piston, volumetric, kapa aseptic).

- Lithanele tse Pholisang.

- Mechini ea ho Paka (ho tiisa, ho ngola mabitso).

Mefuta ea Sauce ea Custard e Hlahisitsoeng

- Custard e sehatsetsing(nako e khutšoanyane ea ho e boloka, tatso e ncha).

- Khasetara ea UHT(e tla phela nako e telele, e hlwekisitswe).

- Motsoako oa Custard o Phofo(bakeng sa ho tsosolosa).

Boiketsetso le Bokgoni

- Mekhoa ea Taolo ea PLCbakeng sa taolo e nepahetseng ea mocheso le ho kopanya.

- Sistimi ea CIP (Hloekisa Sebakeng)bakeng sa bohloeki.

Ho Laela Sebaka

Ngola molaetsa oa hau mona 'me u o romelle ho rona